centrifugal fan blade|industrial centrifugal fans for sale : distributing A centrifugal fan is a mechanical device for moving air or other gases in a direction at an angle to the incoming fluid. Centrifugal fans often contain a ducted housing to direct outgoing air in a specific direction or across a heat sink; such a fan is also called a blower, blower fan, or squirrel-cage fan (because it looks . See more IndoSurgicals is an ISO 9001 certified manufacturer, supplier and exporter of Autoclave and Sterilizer in Delhi, India.

{plog:ftitle_list}

To prevent burns, allow unit to cool before cleaning. Wipe with a soft dry cloth and occasionally with a damp cloth and mild soap or detergent. Drain water from reservoir using drain tube .

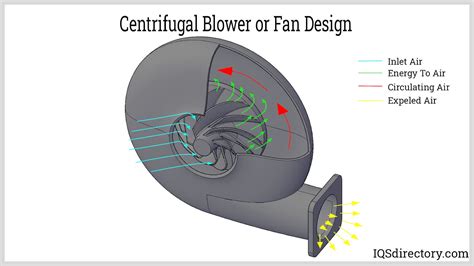

A centrifugal fan is a mechanical device for moving air or other gases in a direction at an angle to the incoming fluid. Centrifugal fans often contain a ducted housing to direct outgoing air in a specific direction or across a heat sink; such a fan is also called a blower, blower fan, or squirrel-cage fan (because it looks . See more

The earliest mention of centrifugal fans was in 1556 by Georg Pawer (Latin: Georgius Agricola) in his book De Re Metallica, where he shows how such fans were used to . See more

The centrifugal fan uses the centrifugal power supplied from the rotation of impellers to increase the kinetic energy of air/gases. When the impellers rotate, the gas particles near the impellers are thrown off from the impellers, then move into the fan casing. As a . See more

Centrifugal fans suffer efficiency losses in both stationary and moving parts, increasing the energy input required for a given level of airflow . See more• Axial fan – Machine used to produce air flow• Ducted fan – Air moving arrangement• Mechanical fan – Machine used to produce air flow• Standard temperature and pressure – Reference values for . See moreThe main parts of a centrifugal fan are:1. Fan housing2. Impellers3. Inlet . See moreRatings found in centrifugal fan performance tables and curves are based on standard air SCFM. Fan manufacturers define standard air as clean, dry air with a density of . See more

In Walter Miller's science-fiction novel A Canticle for Leibowitz (1959), an order of monks in a post-apocalyptic 26th century safeguard an electrical blueprint for a "squirrel cage" as a . See more Centrifugal fans differ from the widely used axial fan design. Centrifugal fans are based around a rotating wheel of blades called impellers, which drag the entering air or gas .

Forward-curved centrifugal fans have impeller blades that can catch and hold debris, making these suitable for filtered or cleaner air applications only. Fans can be equipped with air filters to further improve air quality. These filters are designed to remove small particles and contaminants from the air stream, providing additional protection . To enhance the working efficiency and aerodynamic performance of the centrifugal fan in the air system of a cotton picker, a new type of centrifugal fan blade was designed by extracting the mid-arc section from the prototype blade and integrating an airfoil, which was transplanted and coupled to the mid-arc section. The design aimed to improve the airflow .Empirical investigations of centrifugal fan of centrifugal fan impellers with backward curved blades in a volute casing seemed to confirm the validity of Eqs. (3.5) and (3.6)

The nomenclature of the centrifugal impeller is illustrated in Fig. 3.1.This chapter summarizes Pfleiderer’s classic theory that provides the blade inlet and exit angles β B1 and β B2.One has to keep in mind that several other geometrical parameters, for instance the number of blades and hence the blade spacing, are not provided by this theory. Centrifugal fans, also called Centrifugal blowers, play an essential role in various industrial applications.You will find them widely used in HVAC systems, manufacturing processes, dust collection, and more. This comprehensive guide explores the mechanics, types, applications, and benefits of centrifugal fans, providing a detailed overview that highlights their importance .Radial Centrifugal Fan. In this blower model, air enters the fan with a 90-degree angled position.The flat shape of blades speeds up the rotation, expelling air radially.For this type of fan, a scroll is imperative as it gives the right direction to the flow, transforming airflow into static pressure.. Radial blowers can be used for material handling, and pollution control as they work .The centrifugal fans with backward-curved blades are designed as freewheel fans and do not require a scroll housing. In the case of centrifugal fans with external rotor motors, the motor is positioned in the impeller, ensuring not just optimum cooling of the motor, but also a particularly compact design.

koscot test hard nickel

Learn here about the centrifugal fan vs axial fan and their differences. [email protected]; 718-899-9090; Follow us: . There’s one fixed point in the ceiling that the fan blades rotate around. The fan draws air down from the ceiling, parallel to the axis, and forced straight down to the floor. . Forward-curved centrifugal fans have impeller blades that can catch and hold debris, making these suitable for filtered or cleaner air applications only. Fans can be equipped with air filters to further improve air quality. These filters are designed to remove small particles and contaminants from the air stream, providing additional protection .

Backward curved fans are another type of centrifugal fan commonly used in various industrial and commercial applications. Unlike forward curved fans, backward curved fans have blades that curve away from the direction of the fan's rotation. The blades are typically larger and more curved, allowing for more efficient airflow and pressure generation.

Drive Arrangements for Centrifugal Fans . . . . . . . . . . . . .9-10 Rotation & Discharge Designations for Centrifugal Fans11-12 . designs with 9 to 16 blades of airfoil contour curved away from the direction of rotation. Air leaves the impeller at a velocity less than its .

kpmg numerical test hard

The multi-blade centrifugal fan is commonly used in modern building ventilation and air-conditioning system. However, it does not readily satisfy the increasing demand for energy saving, high efficiency or noise reduction. Its performance is inherently limited by the geometrical structure of single circular arc blades. Q35-type multi-blade centrifugal fan studied as an . The centrifugal fan blade damage identification test rig is shown in Fig. 5. It consists of a centrifugal fan (XFJ-YJ-3.5A, Guangzhou Xinfeng fan Co., Ltd, Guangdong, China), a three-phase asynchronous motor (YVF-90S-2, Deqing Tongda Motor Co., Ltd, Guangdong, China), an inverter (EV4300, Delta electronic enterprise management (Shanghai) Co . Centrifugal fan blades are usually single-arc thin blades with the same thickness, because this can reduce processing costs. The single arc blade used in the project has a simple shape, and its related size parameters cannot fundamentally change the blade profile, and it is difficult to meet the needs of multi-objective optimization design [6]. . With the advantages of compact geometry, large flow rate, and low noise level, the forward-curved blade centrifugal fan, as illustrated in Fig. 1, is widely used in heating, ventilation, and air-conditioning (HVAC) system.In general, the impeller of the forward-curved blade centrifugal fan is designed with a high ratio of inlet-to-outlet diameter and large width with .

3). Radial Fan Blade in Centrifugal Fans. A Radial Fan Blade in centrifugal fans is a mechanical device with an impeller powered by an electrical motor. The impeller rotates independently and directs the air. This air that it works with is normally sucked from the sides of the fan and blown through the fan’s outlet.Radial fans Radial fans have blades, which extend straight from the shaft, and typically have 6 to 16 blades. 1) Simplest of all centrifugal fans and the least efficient. Radial fans have efficiencies of 50 - 65 percent 2) Operate at medium speed and can move air against higher pressures than other centrifugal fans. Types of blades used in centrifugal fans are. Straight steel plate paddle wheel; Forward multi-vane multi-blade; Backward turbo-vane; The different blades can be characterized as shown in the capacity diagram below: Mixed flow fans. In a mixed flow fan the air flows in both axial and radial direction relative to the shaft. Mixed flow fans .The blade of centrifugal fans is specifically mounted on the rotor radially. Airflow direction: The blades are capable of rotating and providing airflow in the parallel direction of the rotor axis. These blades can provide airflow perpendicular to the rotor axis, which in turn helps in the circulation of air throughout. .

types of centrifugal blowers

The shape of your blades and the direction they travel will define the performance characteristics of your fan. Fig 3 shows the velocity diagram for the air flowing into the fan (inlet) and out of it (outlet). v₁ᵢ and v₁ₒ: the inlet and outlet velocities of the air through the blades will be the same for axial fans and different for centrifugal fans v₂ᵢ and v₂ₒ: the circular . Backward-Curved Blades. Centrifugal fans play a crucial role in various applications such as ventilation, firefighting, dust removal, and smoke exhaust. When it comes to choosing the right fan for your needs, understanding the differences between forward-curved and backward-curved blade designs is essential for optimal performance and efficiency.

Centrifugal fans and blowers play a vital role in various industrial and commercial settings, providing efficient airflow and ventilation. Whether it's for cooling, exhaust systems, or air circulation, understanding the basics of centrifugal fans can help you make informed decisions for your specific needs. . Radial Blade Fans: These fans .Centrifugal fans from ebm-papst are available with forward and backward-curved blades. The quiet-running centrifugal fans with forward-curved blades are supplied as motor-impeller combinations or with a scroll housing. The centrifugal fans with backward-curved blades have a free-running impeller and do not require a scroll housing. Huang and Hsieh (2009) used the CFD method in their studies in which they tried to create the optimum design of a back-blade centrifugal fan and reported that they achieved a 7.9% improvement in .shape of the airfoil blade and the optimal blade inlet angle. One feature of centrifugal fan shape design problems is that they require complete regeneration of the mesh in the flow field as the fan geometry evolves, which leads to tedious re-meshing of .

The meshing and simulation procedure followed to simulate centrifugal fan having Z = 11 blades impeller (Section 3.1) is adopted in simulation of other cases (Z = 8, 10, 12, 14). To perform parametric analysis, care is taken to maintain identical mesh and simulation setup for all the cases to achieve accurate results.Backward inclined centrifugal fans have three blade designs: flat single thickness, curved single thickness, and curved airfoil. The blades of backward inclined blowers are much heavier and larger than forward curved centrifugal blowers and move in opposition to the direction of the wheel rotation. The velocity vector for backward curved blade .

industrial centrifugal fans for sale

kpop gender test hard

In generale, l'impianto autoclave è necessario ogni qualvolta la pressione dell'acqua non è sufficiente a raggiungere tutti i locali serviti dalle tubature. Ciò può accadere nei condomini molto alti, con un numero di piani superiore a .

centrifugal fan blade|industrial centrifugal fans for sale